7 Signs Your Diesel Engine Needs Repairs

Diesel engines have earned a solid reputation for durability, high torque output, and remarkable fuel efficiency, which is why so many drivers depend on them for both personal and commercial use. For those with these engines, it's essential to know the crucial signs that fixes are needed, as having this set of knowledge can help you address issues promptly with the support of experienced mechanics. Read on to learn about some major signs that your diesel engine needs to be repaired.

1. Unusual Engine Noises

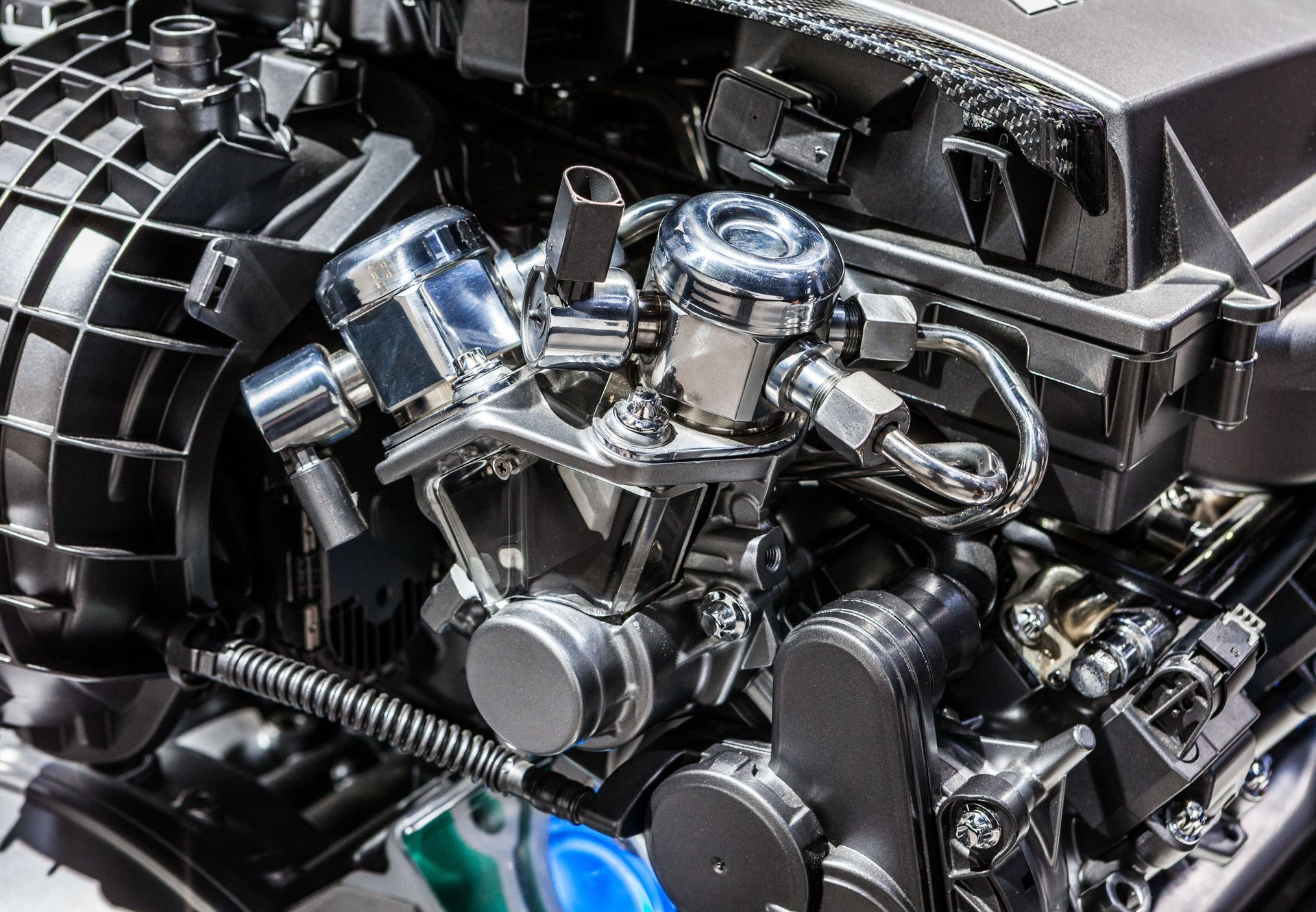

Unusual engine noises can be thought of as your vehicle attempting to communicate that something is amiss beneath the hood. In a healthy diesel engine, the noise profile should remain relatively steady, with a deep, robust hum being a common characteristic. When you hear loud knocking, a pronounced rumbling, or persistent ticking, it generally suggests something is disrupting the normal combustion process or that one or more engine parts are wearing out.

Knocking sounds can stem from faulty fuel injection timing or even the use of incorrect grade fuel, while distinct ticking noises sometimes point to issues with the valves or valve lifters. Although it might be tempting to ignore sounds that come and go, any unusual or persistent noise is a sign that your engine deserves a closer inspection. The longer the noise goes unchecked, the higher the chance of incurring significant damage, such as piston wear, connecting rod failure, or even a cracked engine block in the most severe cases.

2. Rumbling or Vibrations

A diesel engine that begins to rumble or vibrate more than usual is often struggling with balance or alignment problems. In some cases, worn-out engine mounts fail to secure the engine tightly, creating excessive vibrations that resonate throughout the vehicle cabin. Misaligned components or an unbalanced flywheel can also cause disruptive shaking.

Beyond the direct inconvenience, excessive rumbling can accelerate wear on many parts of the engine, leading to additional damage over time. Vibrations sometimes point to partial obstructions or leaks in the exhaust system, which compromise the engine’s ability to expel exhaust gases efficiently. These issues can decrease overall performance and put unnecessary strain on other engine components. Getting a professional evaluation to identify the exact cause of rumbling or shaking is vital if you want to keep your diesel engine running smoothly and avoid compounding mechanical problems.

3. Excessive Exhaust Smoke

While diesel engines typically emit more visible exhaust than their gasoline counterparts, a sudden or dramatic increase in smoke output signals a deeper issue at hand. Changes in smoke color can provide important diagnostic clues. Black smoke often arises from a rich fuel mixture, meaning there is too much fuel relative to the available air. This condition not only affects performance but also raises fuel consumption. If you notice blue smoke, it can be an indication that oil is leaking into the combustion chamber, possibly through worn piston rings or valves.

In contrast, white smoke frequently points to incomplete combustion, which may occur in situations with low compression or poor timing. Monitoring smoke levels and color can be especially helpful for diagnosing trouble areas. As soon as a diesel engine starts releasing more smoke than usual, investigating the air filter, fuel system, or turbocharger is imperative. Occasionally, a simple clogged air filter will be the root cause, while other times, the culprit could be something more serious, such as deteriorating injectors or a failing pump.

4. Difficulty Starting the Engine

Diesel engines operate differently from gasoline engines in that they rely on compression and heat—rather than spark plugs—for ignition. When a diesel engine struggles to start, especially during colder weather, glow plugs are often the first component to check. These small heating elements raise the temperature in the cylinder to facilitate ignition when external temperatures drop. However, if the glow plugs are functioning properly and you still encounter difficulty starting, the battery could be the next area to explore.

A weak or failing battery reduces the cranking speed, making it hard for the engine to reach the necessary compression temperature. Fuel system problems, such as clogged fuel filters or obstructed lines, can also cause hard-start scenarios by restricting the flow of diesel into the combustion chambers. Addressing each of these possibilities—glow plugs, battery health, and fuel flow—can make the difference between a diesel engine that starts reliably every morning and one that struggles repeatedly.

5. Hard Starts in Cold Weather

Although related to the challenge of difficulty starting, hard starts specifically in cold weather deserve separate emphasis because of how sensitive diesel fuel can be to low temperatures. Diesel fuel tends to thicken or “gel” in colder climates, and the thickening process forces the engine to work harder during startup. Oils also become more viscous when the temperature drops, which further burdens the starter motor. Properly functioning glow plugs can offset this issue by generating enough heat to facilitate ignition, but if those plugs are old, damaged, or insufficient in colder weather, the engine will have a rough time getting going.

Another measure to prevent cold-weather start problems involves using winter-grade diesel fuel blends and additives designed to keep the fuel from gelling. These blends work by lowering the cold filter plugging point of the diesel, meaning the fuel remains fluid at lower temperatures. Staying proactive about these winter preparations is important, as repeated hard starts can degrade the starter, battery, and other engine components over time.

6. Loss of Power or Performance

A noticeable drop in power when accelerating, towing, or climbing hills indicates potential troubles within the diesel engine’s core systems. In some cases, a worn or dirty air filter restricts the amount of oxygen entering the combustion chamber, leading to sluggish acceleration and reduced horsepower. Fuel delivery problems, such as failing injectors or a blocked fuel line, can also rob the engine of its usual responsiveness. Turbocharger malfunctions further complicate the picture, as they reduce the forced air entering the engine, lowering its power output.

Any reduction in performance that persists over multiple drives should be taken seriously because it is a clear sign that the engine is not operating at its intended capacity. Drivers who notice difficulty maintaining highway speeds or an inability to handle loads that were once routine should consult a crew of mechanics to diagnose problems in the air intake, fuel system, or exhaust components. Addressing performance-related difficulties early can prevent more substantial damage in the long run.

7. Increased Fuel Consumption

Diesel engines are known for their durability and fuel efficiency compared to gasoline engines, often traveling 20% to 35% farther on a gallon of fuel. This is because diesel fuel contains roughly 10% to 15% more energy than gasoline, according to Boston University, This efficiency is one of the biggest appeals of these engines. When you start noticing that your tank is emptying faster than usual or that the vehicle is covering fewer miles per gallon, you should suspect potential problems with combustion efficiency. Misfiring cylinders, in which fuel fails to ignite properly, can waste diesel and push up both emissions and operating costs.

A dirty or malfunctioning injector can also allow too much fuel to flow into the cylinders, creating a rich mixture that does not combust as cleanly as it should. Restricted airflow from a clogged air filter compounds this problem by making combustion less effective, generating more smoke, and elevating fuel use. Regularly checking and replacing air and fuel filters is one of the simplest maintenance steps you can take to safeguard your fuel efficiency.

Recognizing the signs that your diesel engine needs repairs is key to avoiding costly damages and ensuring your vehicle's reliability. Such vigilance ensures that small issues are addressed before developing into more significant, costlier problems. If you're looking for an expert team of mechanics, look no further than AFS Diesel Truck & Body. We're here to ensure your engine remains a reliable workhorse for years to come, delivering consistent performance and efficiency.

Learn More About

AFS Diesel Truck & Body

Located in Conley, GA. AFS Diesel Truck & Body specializes in truck shop, machine shop, production services, and parts services. We sell heavy-duty trucks and equipment. 24/7 mobile service. Walk-ins welcome. Certified technicians. Call us now.

serving Area

Conley, GA

Georgia

and surrounding areas

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

Mobile Service 24/7, Call for an Appointment

Share On: